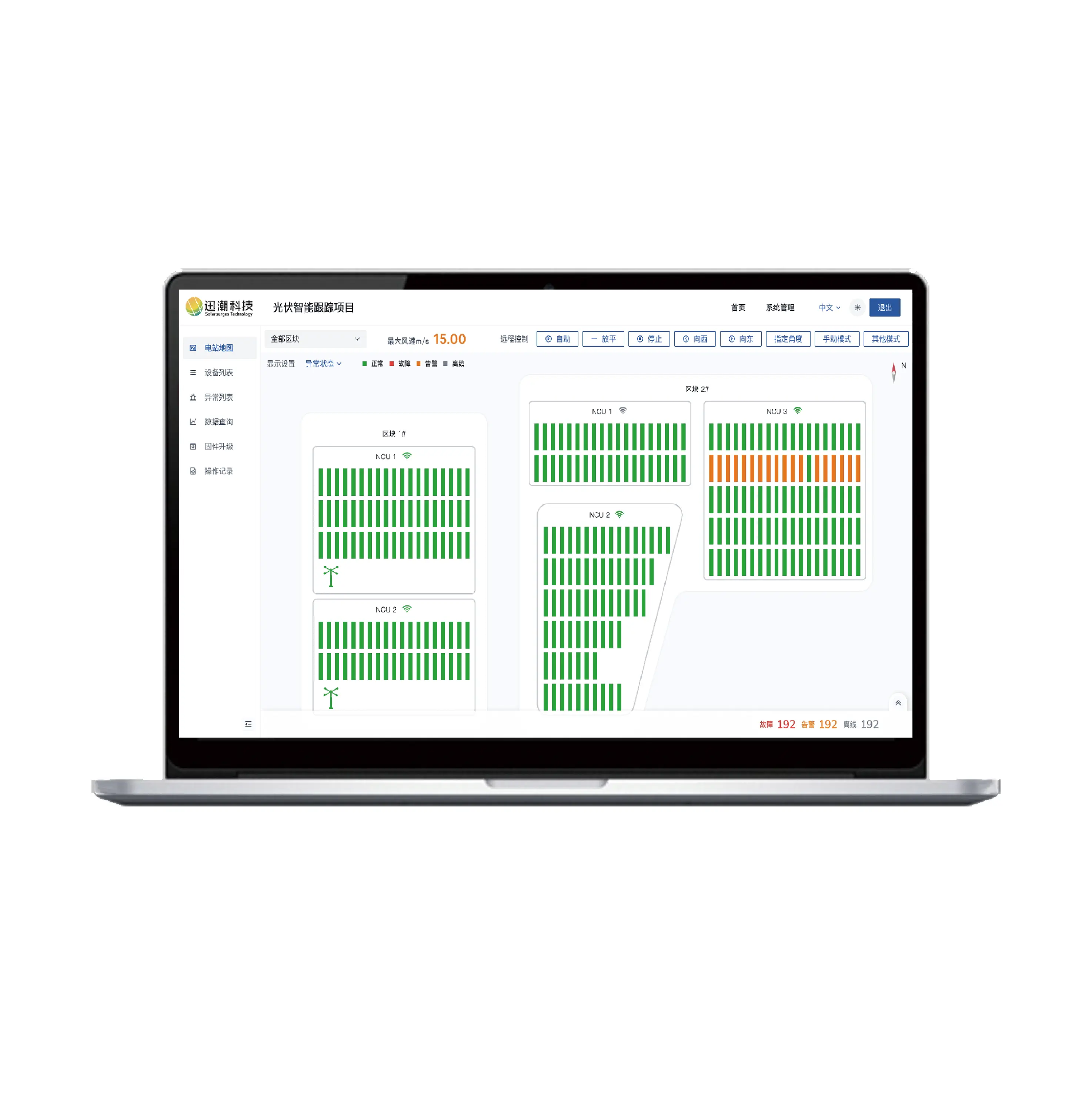

After segmenting customer needs, technicians and sales staff work together to make the process more efficient. Hundred-megawatt monthly production capacity is achieved through quantitative management of dust-free production lines. Modern multifunctional laboratories are the quality guarantee of high-quality products; efficient inventory management, dedicated batch management, ensure consistent quality tracking. It can meet customers' needs for supplying large solar tracking controller projects. Standard factory services include digital warehousing and logistics systems, so that customers can worry-free, monitor the production process in real time, and minimize additional communication and costs, providing the highest level of customer experience with reliable delivery time and minimal on-site processing.

English

English  中文

中文